Precision Instruments

for every medical specialty

Complete Solutions for Medical Technology

From the initial concept to the finished product, we support you with expertise and cutting-edge technology

Custom Manufacturing

Together we manufacture tailored solutions for your requirements – from the first idea to the finished product.

Prototype Manufacturing

Precise prototypes enable you to test and optimize before we move into series production.

Series Production

With state-of-the-art CNC technology, we manufacture efficiently and in the highest quality – from small to large series.

Surface Treatment

High-quality surface finishing for optimal feel and durability of your medical instruments.

CNC Precision Manufacturing

5-axis machining for complex geometries with highest precision and repeatability.

Quality Assurance

ISO 13485 certified processes guarantee the highest quality standards in medical technology.

Products by Medical Specialty

Click on the glowing areas to discover our specialized instruments for each medical specialty

Select a Medical Area

Click on one of the glowing points in the skeleton

to view the associated medical products

ISO 13485 Certified

All products meet the highest quality standards

±0.001mm Precision

Highest manufacturing accuracy for best results

Custom Solutions

Individual manufacturing according to your requirements

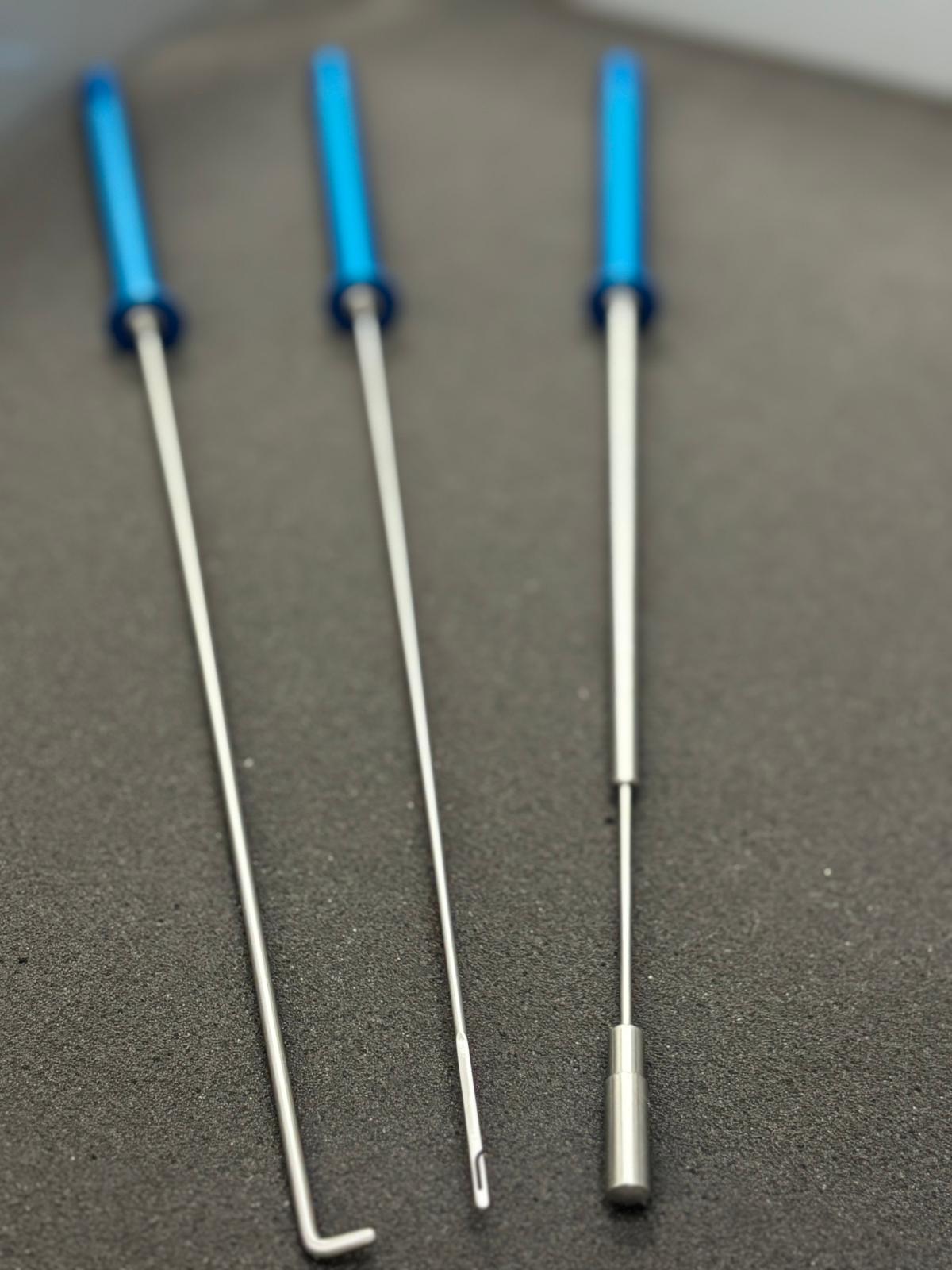

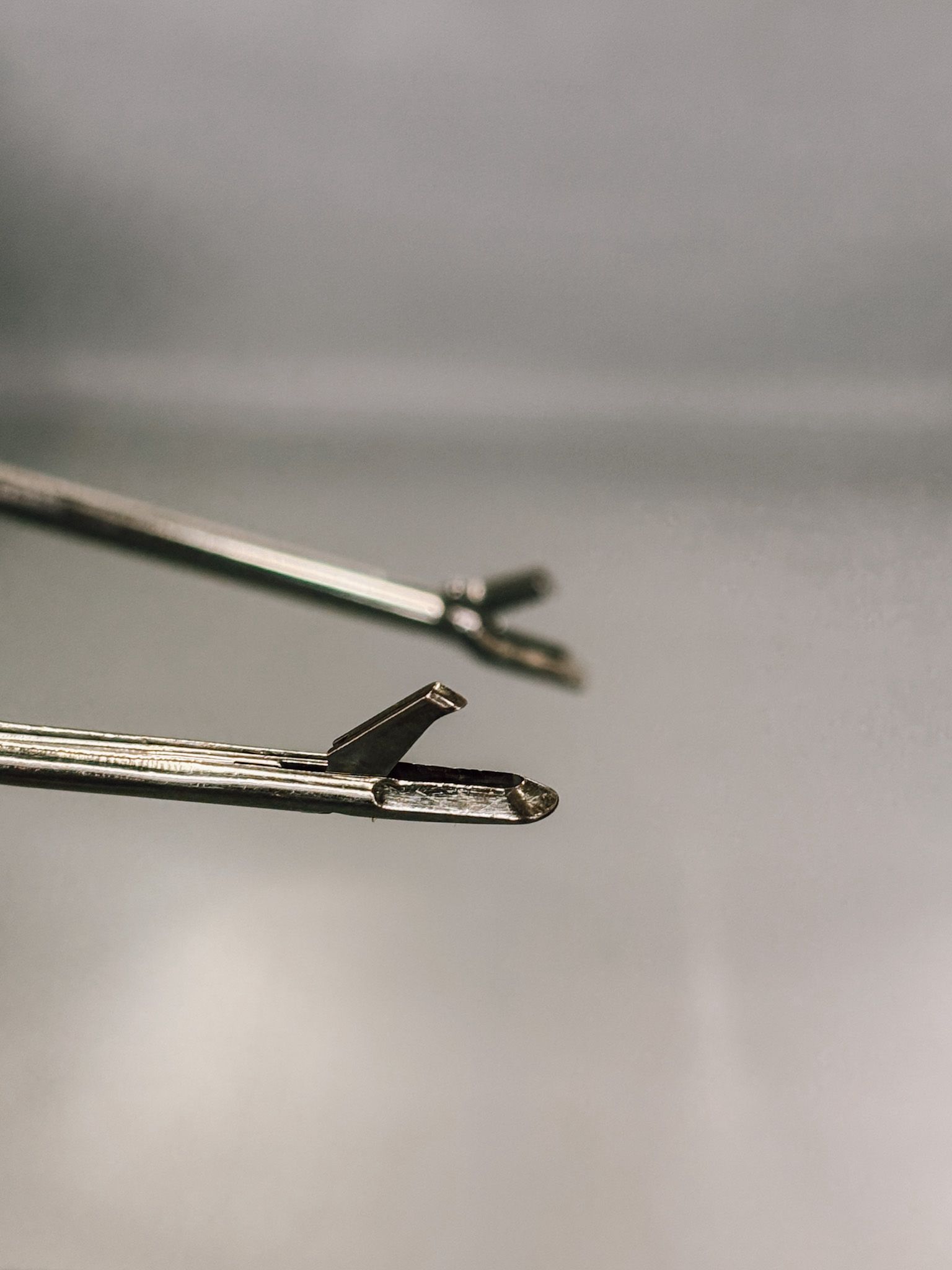

Our Precision Instruments

Selected examples from our portfolio of medical instruments

Our Technology for Your Products

Discover how our state-of-the-art machine fleet determines your product quality

Scroll down

State-of-the-Art CNC Technology

4 high-precision machines for complex medical instruments

Star SR 20

Precision CNC automatic turning lathe for complex small parts

Star SR 20

Precision CNC automatic turning lathe for complex small parts

Hermle C800

High-precision 3- to 5-axis machining center

Hermle C800

High-precision 3- to 5-axis machining center

Hermle C12

Compact 5-axis machining center

Hermle C12

Compact 5-axis machining center

DMG MORI DMU 50 eVo

5-axis machining center with NC swivel/rotary table

DMG MORI DMU 50 eVo

5-axis machining center with NC swivel/rotary table

Additional Manufacturing Processes

Welding technology and surface treatment at the highest level

TIG Welding

Precision tungsten inert gas welding for high-quality, clean welds on medical instruments. Ideal for thin materials and complex geometries.

- Precise welds

- Minimal heat input

- High purity

- For stainless steel & titanium

Laser Welding

State-of-the-art laser welding for minimal distortion and maximum precision. Perfect for delicate components and smallest weld spots.

- Non-contact

- Micro welding

- No post-processing

- Highest precision

Ultrasonic Cleaning

Professional ultrasonic cleaning for perfect cleanliness and surface quality. Reliably removes chips, oils and residues from all cavities.

- Deep cleaning

- Gentle on materials

- Even for complex geometries

- Medical technology standard

Ready for Your Project?

Contact us for a non-binding consultation. We look forward to learning about your requirements.